Blue Bulletin

Majors Industries

September 2025

CO2 Capture:

Accelerating Decarbonization for Industry

CO2 capture is an emerging technology that can enable industrial companies to strengthen and accelerate their decarbonization efforts. It is particularly attractive for industries with high CO2 concentrations in their gas emissions or whose CO2 emissions are inherent to their processes, such as the production of cement and other industrial products. In this article, we invite you to learn more about this technology and how it can help reduce your carbon footprint.

A useful complement to recognized solutions

First, it’s important to note that CO2 capture (CC) is not meant to replace emission reduction solutions such as energy efficiency, electrification and renewable natural gas. However, experts agree that this technology is an essential component of any path to carbon neutrality5 and offers significant potential in efforts to fully decarbonize the industrial sector by 2050. In other words, CC is a solution that optimizes the effectiveness of a decarbonization strategy, particularly for treating residual emissions from sectors that are hard to decarbonize.

How does CO2 capture work?

There are currently three main methods of CC:

- post-combustion capture;

- pre-combustion capture;

- oxy-combustion capture.

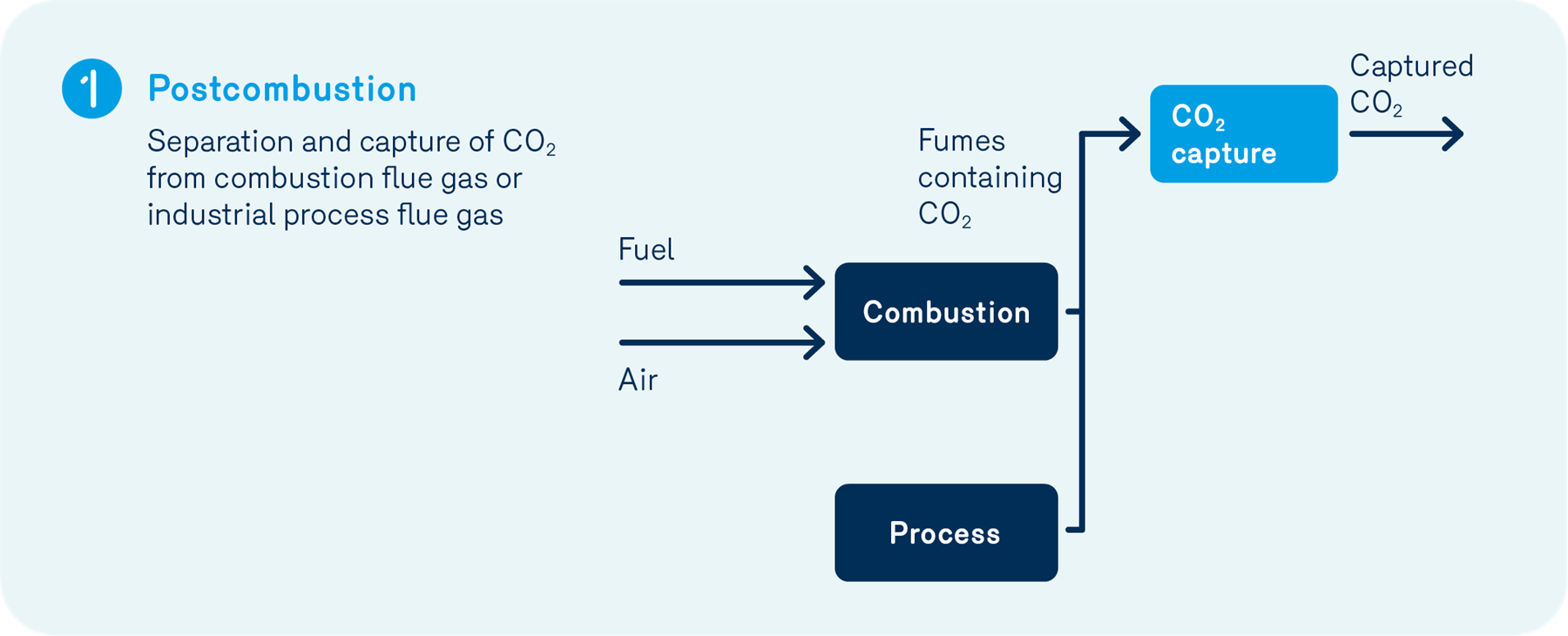

Postcombustion capture is the most common and affordable method, as it can be applied to existing facilities without major modifications. It involves extracting CO2 from flue gas or process flue gas.

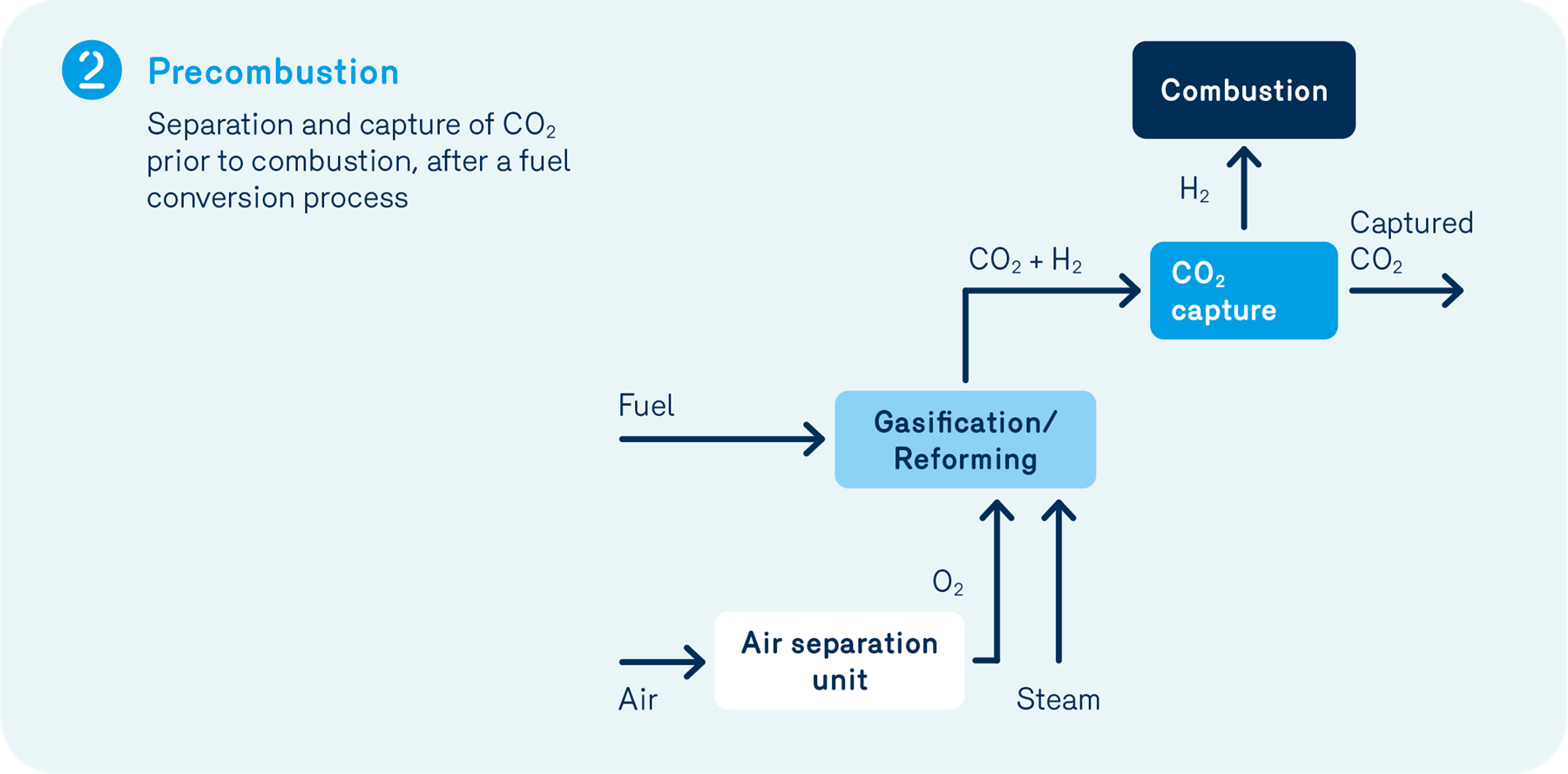

Precombustion capture is a more expensive method that requires specific equipment that must be planned for when the industrial site is designed. It involves removing CO2 from a fuel (such as natural gas or coal) before it is burned. In this method, fuel is converted into a synthesis gas composed mainly of carbon monoxide (CO) and hydrogen (H2) and then reacted with water vapour to produce CO2. The CO2 and hydrogen are then separated: the H2 can be used for combustion or as a raw material, while the CO2 can be captured.

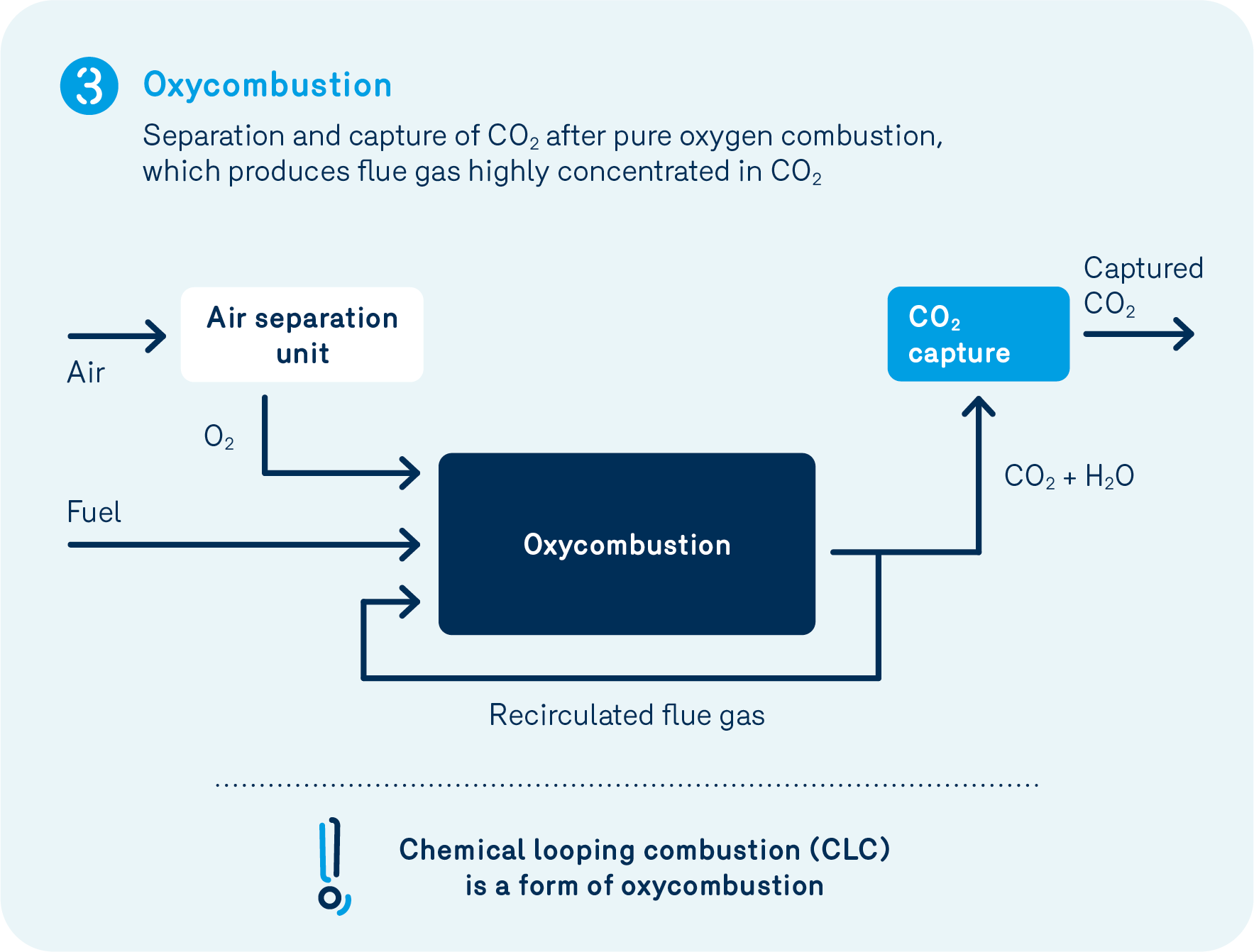

Oxycombustion capture is a method that involves burning a fuel with pure oxygen. The fumes generated from this combustion mainly contain CO2 and water in the form of steam, which is easily separated. However, this method requires the production or purchase of pure oxygen.

Separation and recovery

Regardless of the capture method used, actual CO2 separation requires the use of mature technological processes such as absorption, adsorption, membranes or cryogenics, or emerging processes such as chemical looping, direct separation or biological capture using algae. Each of these processes has its own specific characteristics in terms of cost, energy consumption, performance and footprint. For example, separation by chemical absorption (the most mature and widespread process) offers high CO2 recovery rates and purity, but is very energy intensive. Conversely, membrane separation, a simpler and more compact technology, uses less energy but yields a lower CO2 recovery rate and purity and is applicable to gas emissions with a high concentration of carbon.

Selection criteria

That said, the choice of process depends primarily on specific criteria such as the composition of gas emissions (concentration of CO2 as well as the presence of other components), the quantity of gas to be processed and the CC project timeframe (projects with longer future timeframes may opt for a process still in development). In addition to these criteria, there are secondary parameters such as capture efficiency, the capture cost of CO2 avoided, energy penalties, footprint and the characteristics of the CO2 captured.

For relatively high CO2 concentrations, such as those found in cement plants during the preheating and calcination stages (20–35%), for example, “traditional” processes such as absorption are relevant, but separation can also be achieved through cryogenics or direct separation.

For relatively low concentrations, particularly boiler emissions (10–15%), processes such as absorption, adsorption, membranes or oxy-combustion may be considered

A diverse offering

The variety of CO2 recovery processes currently available gives Quebec’s industrial facilities considerable flexibility in choosing the technology best suited to their specific operations. This provides them with additional means of reducing their carbon footprint in the context of the energy transition and the 2050 deadline.

CO2 promoting competitiveness and innovation

It is also important to note that CC is only the first step in the CO2 chain, which also includes the transportation of CO2 and carbon capture, utilization and storage (CCUS). Overall, this process is seen as an important, if not decisive, decarbonization opportunity for maintaining industrial competitiveness and, more broadly, ensuring the success of the energy transition. Furthermore, implementing CCUS infrastructure can stimulate technological innovation and create new economic opportunities, particularly in the management and utilization of captured CO2.

Énergir is here to advise and support you

Énergir plays an active role in structuring the CO2 value chain in Québec. Initiatives under consideration include the capture and sequestration of industrial CO2, as well as the use of biogenic CO2 to produce third-generation RNG. With its expertise in pipeline transportation, Énergir is also exploring safe and efficient solutions for CO2 transportation.

If you’d like to learn more about this technology, its relevance and its benefits to your business, we invite you to contact your Énergir Major Industries advisor.

Concrete examples of CO2 capture in industrial settings

More and more industrial sites around the world are turning to CO2 capture. Here are some concrete examples of how this technology is being applied in different industries:

- Cement Plants

As part of Project CO2MENT, Lafarge has been capturing a portion of the CO2 from the Richmond, BC, cement plant using adsorption technology since 2019. The project is currently in its third phase, which involves utilizing the captured CO2.

- Refineries

In Alberta, the Sturgeon refinery is capturing CO2 from the gasification of heavy bottoms (precombustion), while Shell is launching its second capture project (Polaris).

- Steam Production

Demonstration of an oxy-combustion steam boiler that runs on natural gas and incorporates carbon capture (Ch0C - Naldeo) in France. This low-carbon boiler is slated for commercialization in 2025.

- Pulp and Paper

Kruger (Wayagamack) announced a demonstration project to capture and reuse CO2 from a natural gas–fired steam boiler using absorption technology.

1 IPCC, IEA (2021) IRENA.

2 10% according to Énergir, 26% according to the International Renewable Energy Agency and 48% according to the International Energy Agency.

3 According to the Technological review of CO2 capture methods Final Report (No. 169224), August 23, 2024, NGTC.

4 Prospective de la CRE” report on carbon capture and the carbon dioxide value chain (in french only)