A Decarbonization Vision for the Industrial Sector

Industrial customers represent both the largest share of natural gas Énergir distributes and the largest share of associated GHG emissions. These emissions represent nearly 60% of Scope 3 GHG emissions downstream of our operations.

In 2022, Énergir started broad discussions on decarbonization efforts by its industrial customers. We met with customers to ask them about this, their ambitions and their decarbonation goals. These discussions continued into 2023 and led to the creation of an industrial decarbonization roadmap.

We need this vision so we can clearly identify solutions that will contribute to decarbonization in the industrial sector and thus adequately support our customers throughout this journey.

For the first time, in our 2023 Climate Resilience Report, we unveiled our strategic vision for full decarbonization of energy distribution to our industrial customers by 2050.

What decarbonization solutions are there for the industrial sector?

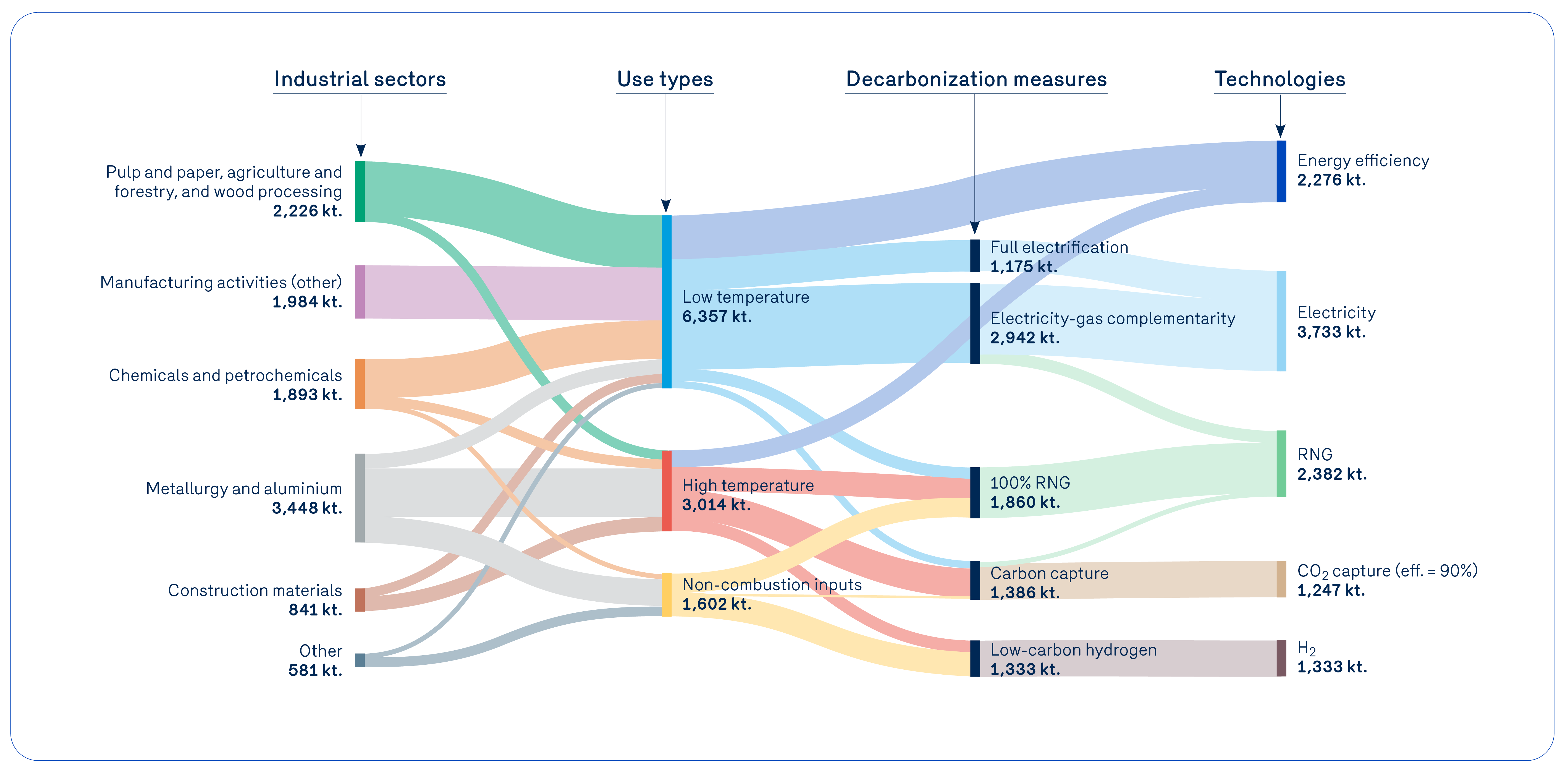

Our vision uses mostly the same decarbonization solutions as those deployed in the building sector, but the solutions are tailored to this large and diverse sector. Our industrial clientele is very diverse and will need many decarbonization strategies and technologies to achieve carbon neutrality.

Our industrial decarbonization vision follows four guiding principles that are based in part on the decarbonization roadmaps of global agencies (International Energy Agency [IEA], International Renewable Energy Association [IRENA]), and an information provider (Bloomberg NEF)1.

- Energy efficiency first and foremost

- Electrification where (use) and when (timing) it works

- The use of technologies under development is a must

- Renewable natural gas (RNG), the keystone to meeting the 1.5°C goal.

Energy efficiency first and foremost

First, consistent with the principles put forward by the World Energy Agency2, Énergir believes that energy efficiency is the first decarbonization measure that should be deployed, given both its multiple societal and economic benefits and its benefits for energy consumers. Énergir has developed energy efficiency programs to maximize volume reductions for its customers over the next few years. These efforts must continue over the long term.

Energy efficiency is forecast to contribute to complete industrial sector decarbonization in the following proportions by 2050:

- According to Énergir: 21%

- According to global agencies: between 8% (Bloomberg NEF) and about 28% (IRENA)

Electrification where (use) and when (timing) it works

While direct electrification from a renewable source is the preferred decarbonization method globally due to its cost, efficiency and small environmental footprint, the industrial sector faces many challenges. Some industrial processes that currently operate on natural gas are very difficult to electrify (e.g., high-temperature processes) or impossible to directly electrify (mainly when natural gas is used as a chemical production input).

Also, where electrification is possible, issues may limit full conversion to electricity. In Quebec’s energy context, where a reliable supply of electricity from the grid has a very high value during the winter, complete electrification can lead to infrastructure over-sizing for only a short interval during the year. For example, for industrial processes that are more easily electrifiable (typically low-temperature processes) and for space heating uses, Énergir is positioning itself so that existing infrastructure reduces the need for new electricity production, transmission and distribution assets (such as the construction of new hydroelectric plants) to enable decarbonization.

Electricity is forecast to contribute to complete industrial sector decarbonization in the following proportions by 2050:

- According to Énergir: 33%

- According to global agencies: between about 15% (IEA) and 27% (Bloomberg NEF)

The use of technologies under development is a must

If direct electrification is more complex, the decarbonization roadmap is less clear as it relies on a mix of technologies under development.

Two technologies that could have a major impact on industrial GHG emissions are carbon capture and low-carbon hydrogen3. Carbon capture currently boasts the most competitive decarbonization costs for large industrial facilities that emit gases with significant concentrations of CO2. It is seen as an essential component of all global carbon neutrality roadmaps (IPCC, IRENA, IEA4). This technology is critical to achieving carbon neutrality since it helps reduce emissions from industrial chemical processes (e.g., cement manufacturing).

Carbon capture is forecast to contribute to complete industrial sector decarbonization in the following proportions by 2050:

- According to Énergir: approximately 10%

- According to global agencies: Between about 26% (IRENA) and 48% (IEA5).

For industrial facilities that rely on processes that are difficult to electrify, low-carbon hydrogen conversion could be a competitive long-term solution. At present, green hydrogen6 produced using renewable electricity and water electrolysis is attracting a great deal of interest. It could become a competitive long-term option. Other technological options to produce low-carbon hydrogen could also come to the fore.

In contrast to RNG, supplies of low-carbon hydrogen, particularly green hydrogen, are expected to be plentiful, which should keep longer-term supply costs under control. Énergir believes that low-carbon hydrogen, just like carbon capture, could prove an excellent additional decarbonization option that would work in a variety of potential industrial sector strategies.

Renewable natural gas (RNG), the keystone to meeting the 1.5°C goal.

Finally, in recognition of the strategic positioning of bioenergy in the decarbonization of sectors that are more difficult to electrify (according to major global decarbonization roadmaps), Énergir believes that RNG is also a must-have option for its industrial customers. RNG is available, interchangeable with fossil natural gas and would enable any industrial customer to both decarbonize the vast majority of its emissions without investing in their facilities and reduce their emissions at a lower cost to society by electrifying operations during off-peak periods and consuming RNG to dodge significant grid investment. In addition, RNG gets us closer to the 1.5°C global warming goal as it would contribute significantly to interim GHG emission reduction targets without requiring full conversion of industrial facilities.

Low-carbon hydrogen and bioenergies are forecast to contribute to complete industrial sector decarbonization in the following proportions by 2050:

- According to Énergir: Approximately 36%

- According to global agencies: Between about 16% (IEA) and 28% (Bloomberg NEF)

Énergir expects these technologies to contribute more because of the significant ability of low-carbon hydrogen and bioenergies (including RNG) to contribute to seasonal peak energy management needs in Quebec’s specific context, i.e., its cold winters.

Since Énergir presumes that the contribution of carbon capture would be lower than that stated in global roadmaps, it follows that the contributions of other measures would be higher.

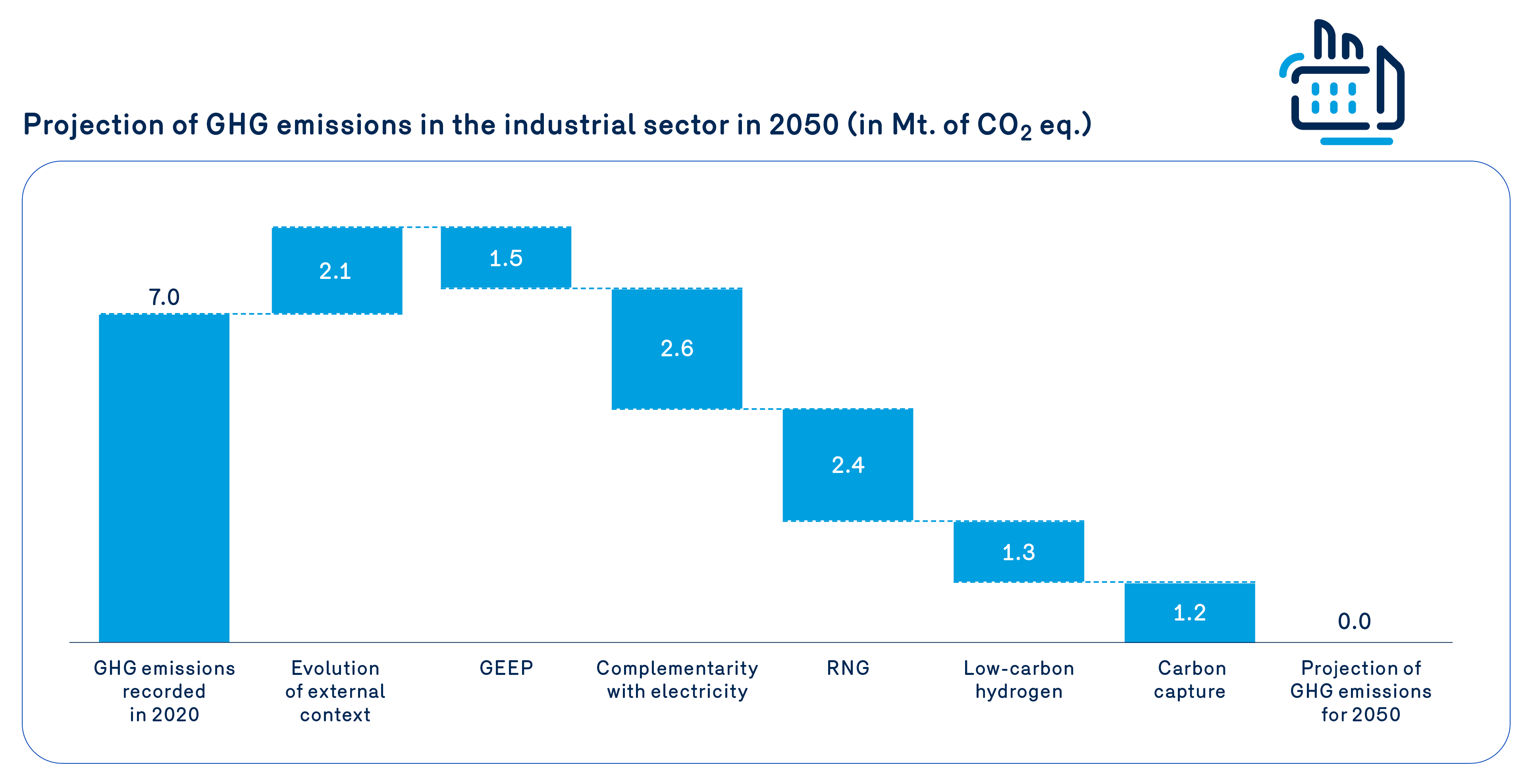

Figure 5 below shows the static forecast in 2050. This forecast is strongly influenced by the decarbonization ambitions of large industrial customers, the regulatory environment and the evolution of technology worldwide.

Note: Energy efficiency is shown as both a decarbonization measure and a grouping of technologies.

Roadmap 2050

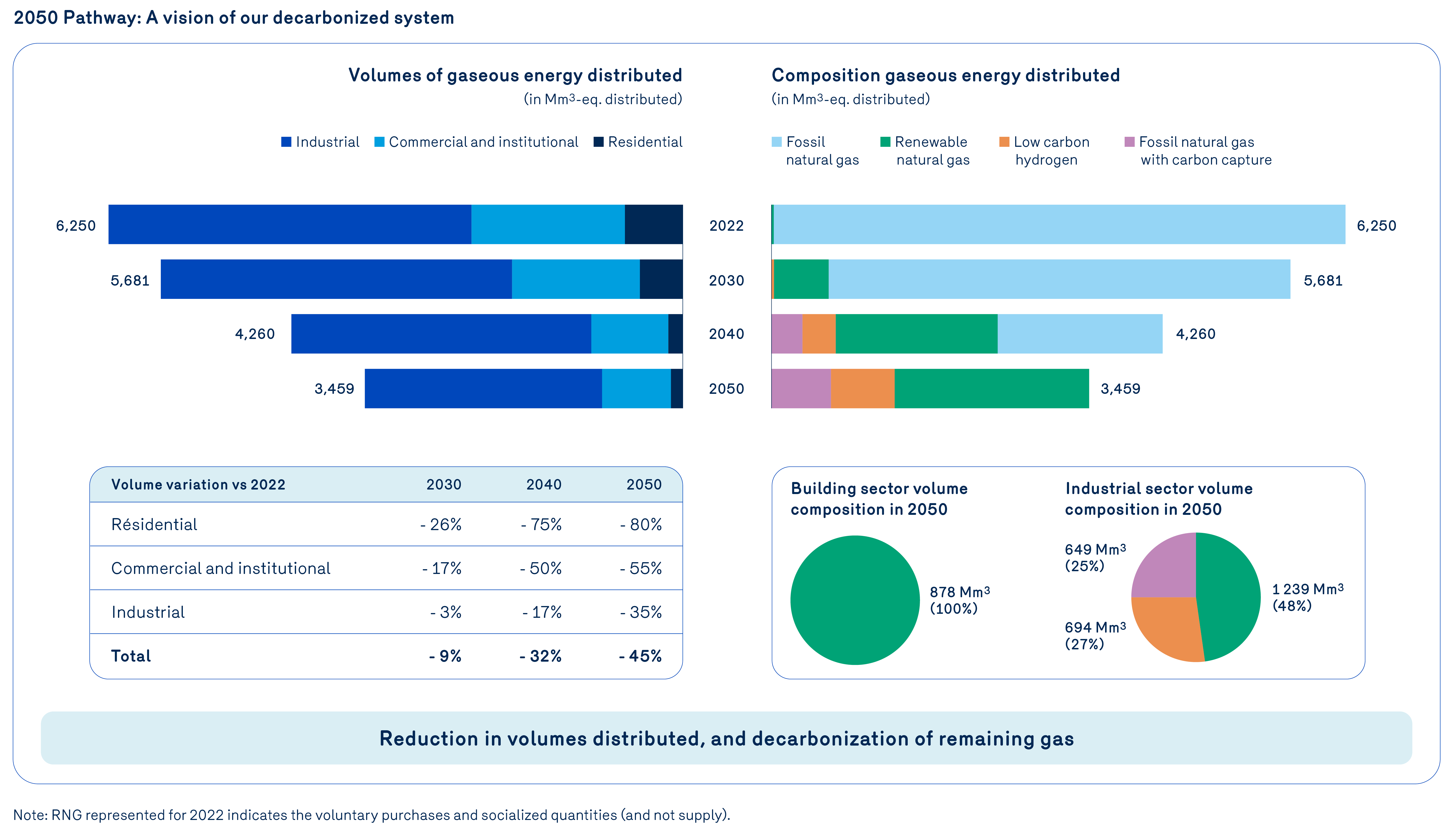

By following this industrial sector decarbonization roadmap, Énergir anticipates a 45% decrease in gas volumes distributed by 2050 as a result of our strategic initiatives, and that remaining volumes will be decarbonized using RNG, low-carbon hydrogen and carbon capture technologies.

For the industrial sector, this trend will start slowly, but is expected to accelerate in 2030 to reach a 35% volume decline by 2050.

To learn more about Énergir’s decarbonization roadmap, refer to our 2023 Climate Resilience Report, pages 27–31.

1. IEA (2021) IRENA (2020), BNEF—New Energy Outlook (2022). In this section, the roadmaps of these agencies are linked to Énergir’s industrial decarbonization roadmap, which also incorporates specifics of Quebec’s context and the composition of its industrial clientele.

2. International Energy Agency—Energy Efficiency 2022 (https://www.iea.org/reports/en...)

3. Low-carbon hydrogen is hydrogen produced using biomass, renewable resources and nuclear power, as well as fossil fuels when carbon capture, utilization, and storage (CCUS) techniques are used and emissions from fossil fuel extraction and procurement are mitigated CER — Market Snapshot:Carbon capture, utilization, and storage market developments (cer-rec.gc.ca)

4. IPCC, IEA (2021) IRENA.

5. Reported values for the contributions of carbon capture and other measures in the IEA roadmap also includes energy source conversions to cleaner fossil fuels.

6. There are various technologies for producing hydrogen. Depending on the process chosen, the hydrogen obtained can be described as black, grey, blue, green, etc. Assigning a colour to the hydrogen is a graphic way of reflecting its origin, that is, the material and energy sources used to produce it. Hydrogen can be produced using water electrolysis (the process of passing an electrical current through water to break down its molecules [H2O] and extract its hydrogen). If the current used also comes from a renewable energy source, all elements of the production cycle are low carbon. The hydrogen produced is called green hydrogen.

7. Includes Énergir’s freight transportation sector service operations.